Introduction

In medical and equipment manufacturing, acrylic is prized for optical clarity, yet CNC Machining Parts often suffer from edge cracking and haze, causing high scrap rates. Integrating advance CNC machining with precise thermal control, ISO-certified quality checks, and customized design ensures consistency and reduces defects .

How to Optimize Acrylic Machining Quality with Advanced CNC Technology?

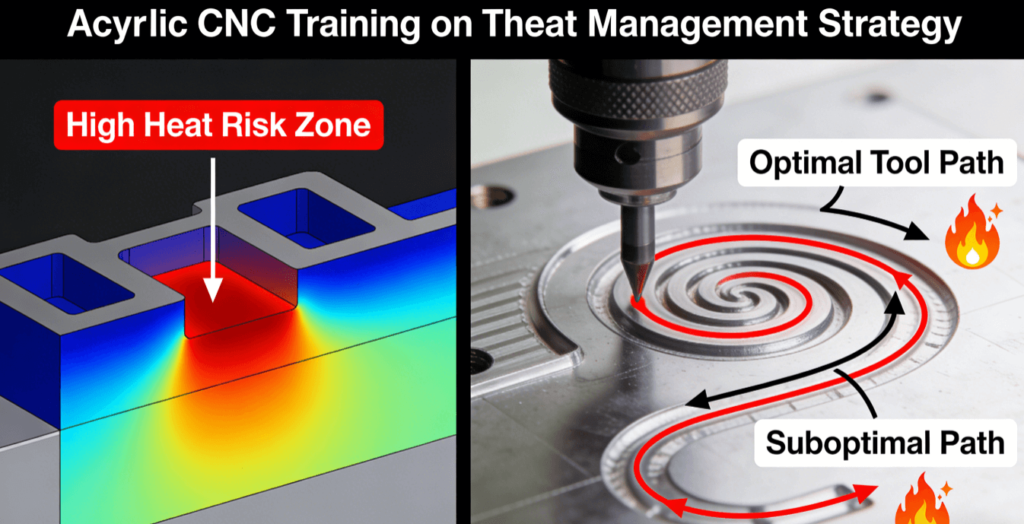

The quest for quality in Acrylic components is dependent on proper thermal sensitivity. Poor heat treatment and machining result in component softening or melting and stalling or internal stresses manifested as micro-cracks and cloudiness.

Core Challenges in Acrylic Processing

The major problem faced in Acrylic CNC Machining is generation of heat. Too much heat can damage the surface integrity of materials. The method adopted traditionally in machining usually can’t handle it effectively. Choosing proper cutting tools and shapes can be equally problematic. Some shapes may increase stresses and not create a clean shear plane.

Technological Solutions for Superior Outcomes

Advanced CNC technology provides a formidable solution to these challenges. By leveraging state-of-the-art equipment and refined processes, manufacturers can achieve remarkable improvements.

- The Role of Multi-Axis Machinery

Utilizing 5-axis high precision CNC technology allows for complex, continuous tool paths that minimize tool engagement and cutting forces. This results in significantly lower heat generation and reduced mechanical stress on the workpiece. According to the American Society for Precision Engineering (ASPE), controlling stress is paramount for maintaining dimensional stability and surface quality in thermal-sensitive materials . The smooth, uninterrupted motion of 5-axis machines facilitates even heat distribution, directly countering the causes of deformation and cracking.

- Precision through Parameter Optimization

The benefits associated with modern machine tools are possible only when optimal machining parameters are adopted. A technique involving fast spindle speeds and low feed rates, together with pointed single flute tools, promotes a clean-cutting process resulting in efficient removal of chips and heat. The application of these optimal machining parameters has also enabled the reduction of defective products from 20% to well below 5%. For more insights into optimal cutting tool selection, refer to this complete Acrylic CNC Machining Guide .

A systematic process is supported by optimized quality management practices, such as ISO 9001 certification, which assures that all processes are carefully documented, adhered to, and continually improved, resulting in consistency.

What are the Key Factors to Consider When Choosing CNC Machining Suppliers?

Selecting the right partner for CNC machining suppliers is a critical decision that extends beyond price. An unsuitable choice can compromise the entire project. Key evaluation criteria for a reliable Precision Manufacturing Services provider include technical capabilities and quality certifications.Technological capability of the supplier is fundamental. It is imperative to ensure that they have current technology like 5-axis CNC mills to cater to the requirements of Acrylic.

Additionally, adhering to global standards is not negotiable to ensure a supplier is keen on quality. Technological certifications such as ISO 9001 (Quality Management) and related industry technology like AS9100D for aerospace quality are a clear way of ensuring a controlled and accountable environment is followed. They are also clear about their quality control activities and issue individual inspection reports like CMM.A possible common mistake could be to concentrate on the lowest bidder. The lowest bidder could be indicative of a set of compromises in terms of material strength, processing speed, or the quality of inspection.

A possible way to mitigate the risk of not selecting the right supplier could be to perform an audit of the supplier’s facilities, whether physical or virtual, along with an evaluation of case studies involving their past work with similar materials, especially when it involves the case of clear polymers. A good supplier should be able to share details about their own capabilities without being prompted to perform a manufacturability report of the materials provided.

What are the Best Practices for Custom Part Design in Acrylic Projects?

Success in Acrylic projects begins with superior Custom Part Design. This phase is not just about creating a 3D model but involves integrating Design for Manufacturability (DFM) principles from the outset to prevent costly errors downstream.

Foundational DFM Principles

Manufacturing experts should be consulted right from the design stage. For example, Acrylic is relatively brittle and requires avoidance of seams with right-angle turns and sufficient wall thickness and fillet design. Also, where components demand greater clarity, tool path planning will be necessary to prevent visibility of marks on important surface areas.

Collaborative Design Optimization

Close collaboration between design and manufacturing teams ensures that parts are not only functional but also producible. This synergy allows for optimizing designs for efficiency and cost-effectiveness.

- Designing to Mitigate Defects

Features like thin walls can be reinforced with ribs to enhance rigidity. The placement of mounting holes should be sufficiently distant from edges to maintain structural integrity. Research from organizations like EUSPEN (European Society for Precision Engineering and Nanotechnology) highlights that anticipating and avoiding design-induced stress concentrations is critical for achieving micro-scale stability, a principle that applies to macro-scale Acrylic machining as well . Proactively addressing these factors during design prevents failures during or after machining.

- Leveraging Prototyping for Validation

Before embarking on large-scale production, using Rapid Prototyping Solutions for creating functional models is an extremely useful initial step. This enables testing in real conditions for functional fit, optical, and mechanical performance.

Streamlining the Path to Production

The ultimate goal of a well-executed Custom Part Design is a smooth transition to reliable manufacturing. A design that minimizes the number of required setups, optimizes tool paths, and efficiently nests parts on the raw material sheet not only improves quality but also reduces production time and material waste. To explore how expert advance CNC machining services can bring your custom designs to life, visit this resource: advance CNC machining .

How Can Rapid Prototyping Solutions Accelerate Acrylic Part Development?

In a fast-paced market environment, speed is a major differentiator. Rapid prototyping solutions give the much-needed boost to the development process of Acrylic components. In conventional prototyping methods, it used to take weeks to proceed from design to a prototype that could be test-assembled. Prototyping using CNC technology enables a reduction in this time frame to just a few days.

Components for functional verification and assembly evaluation can be realized using the final material.Data from practices in the industry reveals a reduction of up to 50% in development time by incorporating rapid prototyping. This is because rapid iteration is possible, so if a mistake is noticed in the prototype, it is possible to change it and make a new one in a matter of minutes, without incurring the high costs of changing the tooling.

The trend is to seamlessly integrate rapid prototyping with batch production. This is because using the CNC Machining Parts process in both rapid prototyping and mass production means that it is possible to obtain a high degree of confidence in the performance of the prototype to predict the performance of the final product.

How Do Precision Manufacturing Services Ensure Consistency in CNC Machined Parts?

For production batches, the excellence of a single part is insufficient; consistency is the definitive metric for Precision Manufacturing Services. Achieving this requires a holistic system of controlled processes and rigorous verification. Consistency is ensured through a multi-layered quality control regimen. In-process inspections monitor critical dimensions during production.

Post-production, devices like coordinate measuring machines (CMM) are used for comprehensive first article inspection (FAI) and random audits. More importantly, Statistical Process Control (SPC) methodologies are employed, where production data is continuously collected and analyzed to identify and correct process deviations before they result in non-conforming parts.As standards bodies talk about, consistency is built on standardization. Beyond baseline ISO 9001, certifications such as IATF 16949 for the automotive industry force even stricter process control and traceability systems.

For a high-quality CNC machining parts factory, value can be delivered in part number 1,000 with the same or even higher accuracy as part number one within the necessary tolerance band. The goal is to have almost zero defect rates of batch production so that reliability and efficiency can be set forth for the client.

Conclusion

This analysis has systematically addressed the critical challenges in Acrylic CNC machining, from edge cracking and transparency loss to high scrap rates. The underlying issues of outdated technology and insufficient process control can be effectively overcome by adopting a integrated strategy.

To improve your results in manufacturing, consider working with a professional with the following expertise. Use the resource libraries for personalized cost analysis and manufacturability analysis for your proposed project.

Author Bio

This article was contributed by a precision manufacturing expert at JS Precision, a team with over 15 years of experience specializing in ISO-certified CNC machining solutions.

FAQs

Q1: What is the maximum size limitation for Acrylic CNC machining?

A: The maximum size is typically determined by the machine’s work envelope, often up to 2500x1800mm, with thicknesses from 1-100mm. For larger requirements, bonding techniques can be explored, though structural integrity must be evaluated. It is best to consult with a supplier for a custom solution .

Q2: How to prevent edge cracking in Acrylic machining?

A: Prevention involves the use of specialized tooling, high spindle speeds and low feeds, as well as good air cooling to accommodate heat. Stress concentration in workpiece clamping is also important in ensuring smooth edges without any cracks.

Q3: What file formats are generally required for Custom Part Design?

A: These are for computer numerical control programming. Details should come with the design in the form of print documents. Suppliers also give feedback on DFM.

Q4: Is Rapid Prototyping applicable to high precision Acrylic components?

A: Yes, the prototyping techniques such as CNC machining have an accuracy capability of ±0.005mm and are suitable for functional verification. However, to produce it at a most economical scale, it is recommended to shift to a volume-optimized process.

Q5: What is the typical Minimum Order Quantity (MOQ) permitted at Precision Manufacturing Services?

A: MOQs will vary. MOQs are often flexible. Prototype orders can range from one unit through to batch sizes that are negotiable. This could include part complexity and materials.